Some might think 4D printing is just a futuristic concept, but it’s already shaping how products adapt over time. These smart materials can change shape, repair themselves, or respond to environmental changes after manufacturing. This technology isn’t just a novelty; it’s transforming industries by making objects more durable and versatile. But how exactly do these materials work, and what could they mean for the future of design and functionality?

Key Takeaways

- 4D printing uses stimuli-responsive materials like shape memory alloys and self-healing polymers that change shape over time.

- External triggers such as heat, moisture, light, or magnetic fields activate material transformations post-manufacturing.

- These materials enable objects to morph, deploy, or repair themselves, creating adaptive and dynamic structures.

- 4D printed morphing materials support applications in aerospace, medical devices, robotics, and smart structures.

- The technology enhances product durability, sustainability, and functionality by allowing post-production shape changes.

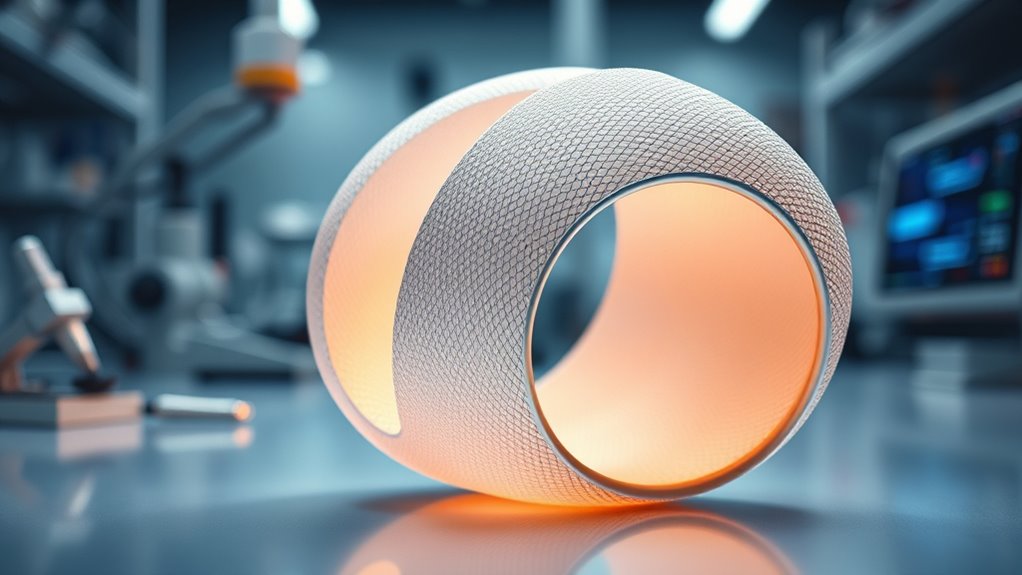

Have you ever wondered how 3D printing could evolve beyond static objects? 4D printing takes this technology a step further by creating objects that can change shape or properties over time in response to external stimuli. Imagine a product that adapts to its environment, repairs itself, or shifts form when needed — that’s the power of 4D printing. This innovation relies heavily on advanced materials like self-healing polymers and shape memory alloys, which give these objects their dynamic capabilities.

4D printing creates adaptable, self-healing objects that respond to external stimuli, transforming industries with smart, dynamic materials.

Self-healing polymers are at the forefront of this revolution. These materials can repair themselves after damage, much like biological tissues. When a crack or break occurs, the polymer’s built-in healing agents activate, restoring the integrity of the object without needing external intervention. This feature is especially useful in aerospace, automotive, and medical devices, where durability and longevity are critical. By integrating self-healing polymers into 4D printed objects, you can create structures that not only change shape but also recover from wear and tear over time, extending their lifespan and reducing maintenance costs.

On the other hand, shape memory alloys (SMAs) bring a different kind of transformation to the table. These metals can remember and return to a predefined shape when exposed to specific stimuli, typically heat. For example, a 4D printed component made with SMAs might be compact during transport and then expand or reshape when heated to its operational environment. This property enables the creation of deployable structures, flexible medical stents, or adaptive aerospace components. When combined with 4D printing techniques, SMAs allow you to design objects that seamlessly morph into complex forms, disclose new possibilities in robotics, aerospace, and wearable tech.

The real magic happens when these materials are programmed to respond to external stimuli such as temperature, moisture, light, or magnetic fields. You could print an object that changes shape when exposed to body heat, making it ideal for personalized medical implants. Or you might develop a structure that morphs in response to environmental conditions, optimizing performance without manual intervention. The integration of self-healing polymers and shape memory alloys into 4D printing expands your capacity to produce smart, adaptable, and resilient objects, pushing the boundaries of what’s possible in manufacturing.

In addition, advancements in quieter heat pump technology are making home heating systems more comfortable and less disruptive, which is especially important when considering retrofitting existing homes for energy efficiency. Whether you’re designing adaptive structures or improving indoor environments, the potential of these advanced materials and technologies opens up a future of smarter, more sustainable, and more resilient products.

Conclusion

As you explore 4D printing, remember it’s like giving materials a mind of their own—responding and adapting to their environment. This technology is shaping the future, turning static objects into living, breathing entities that can heal, reshape, and evolve. Embrace the potential, because you’re not just building with materials anymore—you’re opening a universe of possibilities where innovation flows as naturally as water finding its path. The future is morphing right before your eyes.